H SERIES GLOSS GUIDE

HOW DO I GET CONSISTENT GLOSS LEVELS, OR CHANGE THE GLOSS LEVEL?

Cerakote gives you the flexibility to customize your gloss levels across multiple substrates. This guide will assist you in achieving the gloss level that meets your requirements.

Standard Gloss Procedure

Catalyst Mixing Ratio: 18:1 (coatings:catalyst) by weight. Mixing by volume is optional.

Ambient Flash: Best practice is to set aside coated parts for a minimum of 15 minutes, but no more than 2 hours, before oven cure.

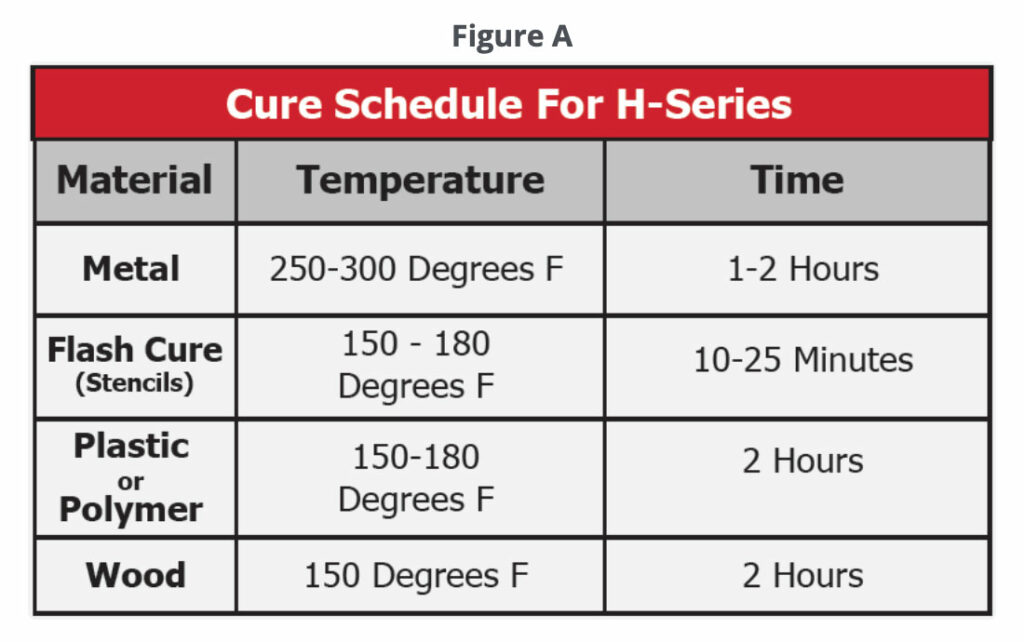

Recommended Cure Schedule

-

Coating a project with a single substrate (metal only, polymer or plastics only, etc.)

Fully cure all parts according to cure schedule (see Figure A) -

Coating a project with multiple substrates (metal and polymer or plastic pieces, etc.)

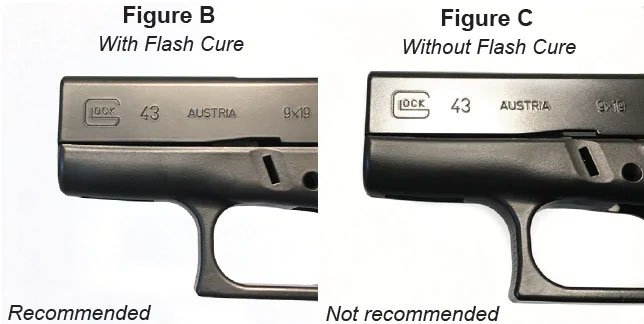

Flash cure all parts at 150°F to 180°F until tack-free (10 to 25 minutes) to lock in gloss on all substrates (see Figure B and C)

Separate all parts according to substrate cure schedule and complete final cure (see Figure A) -

Note: Some Cerakote coatings require specific cure schedules.

Always review the product specific Technical Data Sheet (TDS) prior to curing.

Why different cure temperatures? Many items, for example firearms, are built from multiple substrates such as polymers and metals. Substrates, like plastic/polymers, have lower temperature stability, and therefore require lower cure temperatures.

IMPORTANT: If you are unsure as to the temperature stability of your parts, contact the manufacturer prior to oven cure.

CUSTOM GLOSS PROCEDURE

Customize your gloss level by changing your standard procedure. Adjusting the Catalyst mixing ratio or cure schedule will give you a lower gloss, standard gloss, or a higher gloss finish. Use one or both variables to achieve your desired finish. The Catalyst mixing ratio is the preferred method to adjust gloss levels. Modifying the cure temperatures should only be used when Catalyst adjustments are not sufficient.

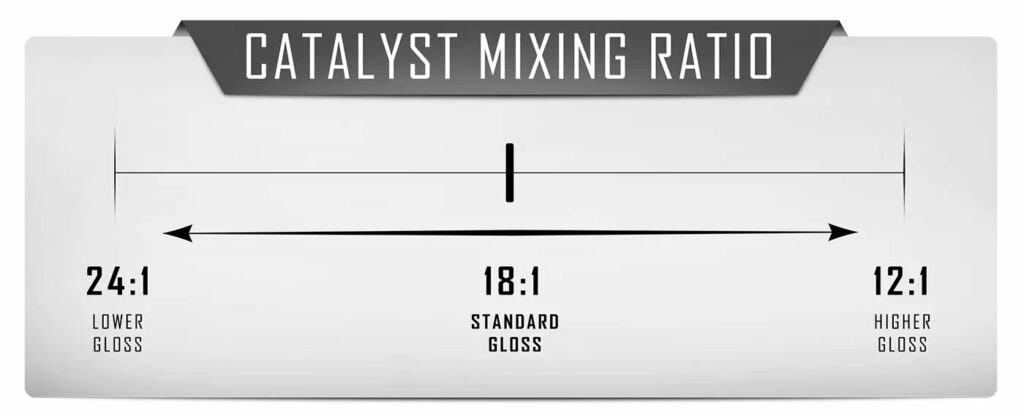

Catalyst Mixing Ratio

Adjust your Catalyst mixing ratio to achieve your desired gloss level.

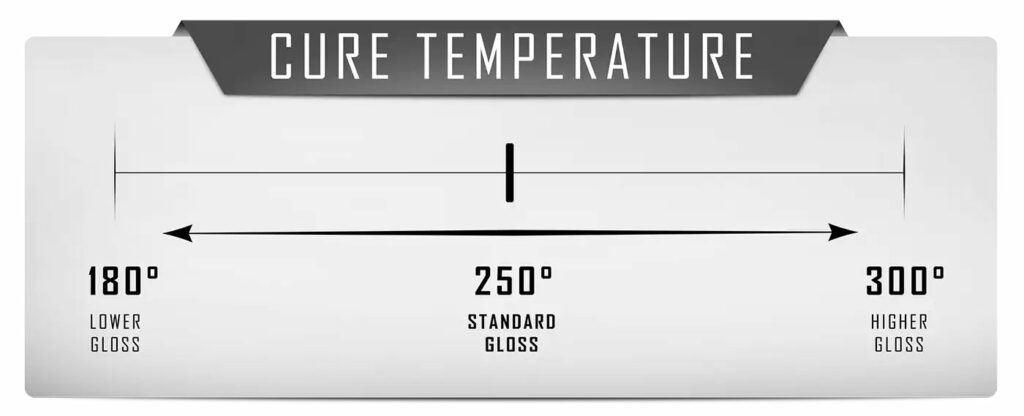

Cure Temperature

Increasing or decreasing cure temperature will raise or lower gloss.

NOTE:

Gloss units and levels are measured at a 60° angle, 18:1 catalyst ratio, 1-2 mil dry film thickness, 15 minutes ambient flash after application, 250°F cure for 2 hours. Adjustments to these conditions will yield different results. Gloss is affected by spray technique and quality of preparation and finish.